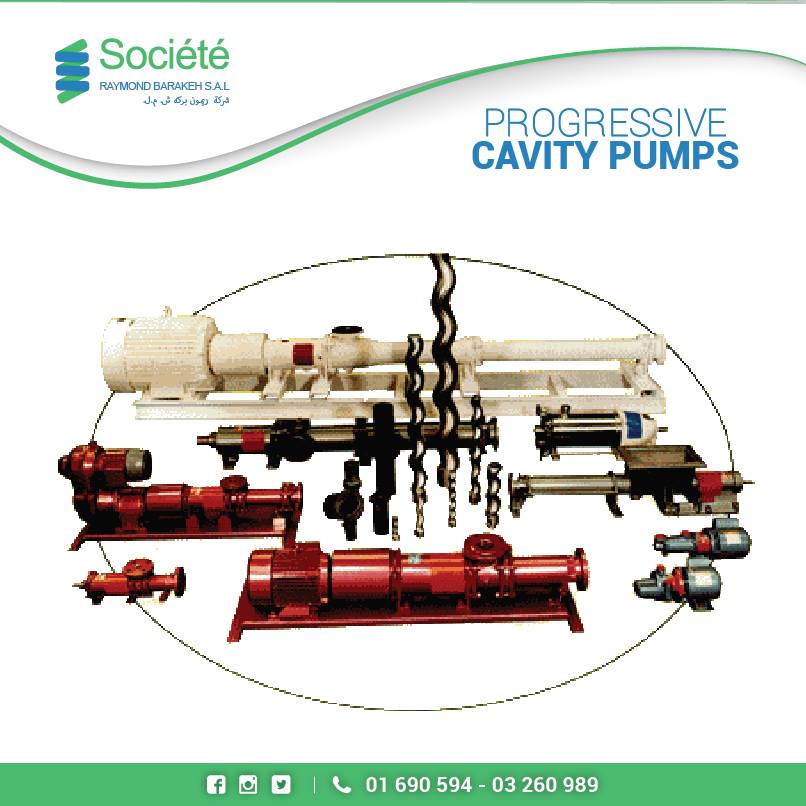

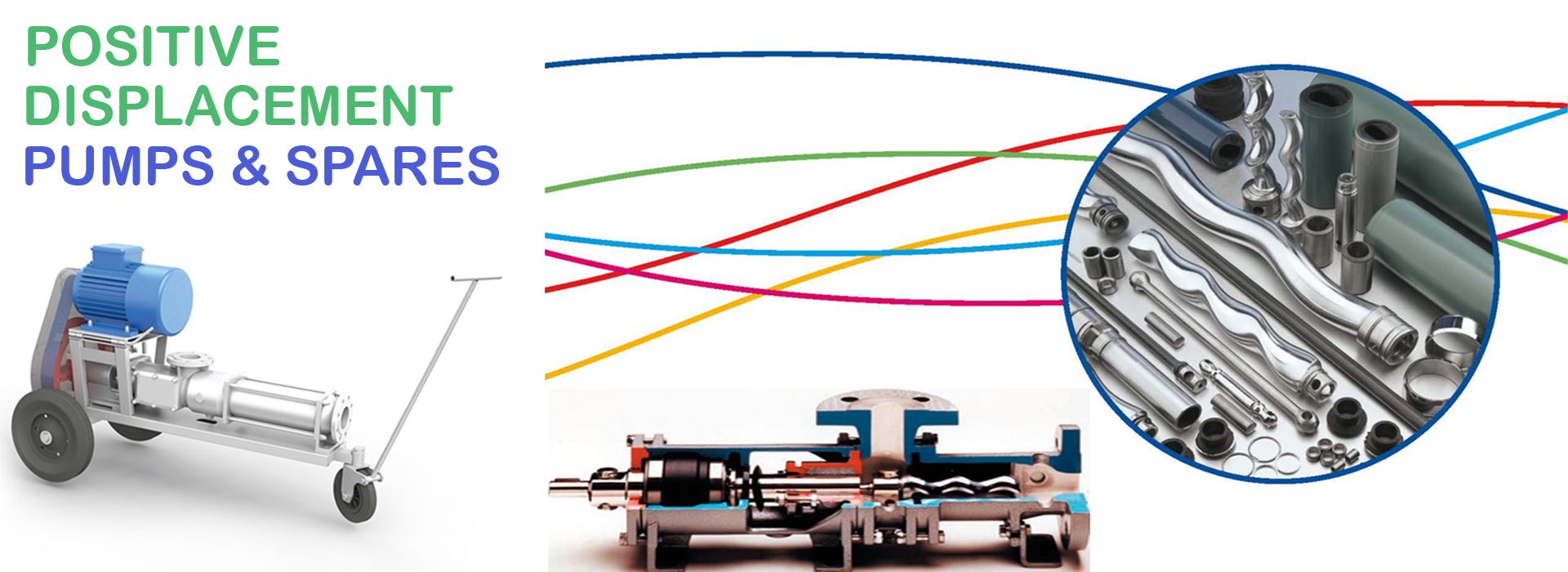

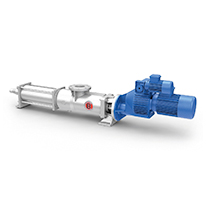

Positive displacement pumps or Eccentric screw pumps are heavy duty pumps and they can be used to pump abrasives sludges, viscous products, oils, emulsions etc.

Due to the steady non turbulent flow they can also handle shear sensitive products and medium with solids content without breaking up the solids.

The progressive cavity pump principle is ideal for handling slurries, viscous, shear sensitive or two or tri phase mixtures or when applications require, significant suction lift capabilities.

The pump design is ideally suited for both low to high flow applications and also allows for the development of multi-stage pumps that increase the pressure handling capabilities.

The heart of the Helical pump is the rotor and stator. As the rotor revolves eccentrically within the stator, a continuous cavity is formed and progresses towards the discharge end of the pump as the rotor rotates.

Installed vertically or horizontally

Industrial pump

Screw pump

Wide range of flows & pressures

Food pump

Characteristics:

| - Positive displacement reversible self priming action. |

| - Uniform Flow. - Simplicity. - Abrasion resistance. |

| - Versatility. |

| - Slow Speed. |

| - High efficiency over wide performance range. |

Benefits:

| - High suction capability |

| - Self-priming operation with suction lifts up to 8.4 m of water. |

| - Uniform flow with minimal pulsation avoids risk of damage to delicate shear sensitive products. |

| - Simplicity of design |

| - No values, only one gland which is usually arranged on the suction side. |

| - Abrasion resistance. |

| - Pumping elements endure abrasive conditions for longer than those of other pump types. |

| - Versatility. |

| - Ability to pump substances that are gaseous free flowing or highly viscous. |

| - ÙAbility to pump products which include solids in substance. |

| - Maintenance is minimal and the few parts subject to wear can be easily replaced on site by unskilled labor. |

| - Head is independent of speed. |

| - Capacity is approximately proportional to speed. |

All wetted parts are available in cast iron, stainless steel, cast steel, Hastealloy B/C , Duplex Steel, Monel steel and other exotic alloys The rotating parts are available in materials from Alloy Steel to AISI D3, 202, 410, 304, 316 and Hastealloy C & B, Monel and other exotic alloys. Stators are available in a variety of elastomer materials from light to dark, such as NBR, EPDM, Hypalon, Silicone, Viton, HNBR.

Progressive Cavity Pumps which are also commonly known as Eccentric Screw Pumps / Helical Rotor Pumps / PC Pumps. The main component which characterize these pumps are a metallic single helical rotary part ROTOR and a fixed double helical resilient Polymer part STATOR in which the rotor turns and thereby a complex progressive sealing line is maintained. Whilst the rotor rotates inside the stator, the cavities formed between them progresses from suction to discharge end gently carrying the media.

Although we do keep some pumps as ready stock, normally lead times vary from 3-12 weeks depending on pump size, type, quantity and special constructional features...etc

We have over 5 decades of experience

Capacities up to 420 M3/Hr and Pressures up to 36 Bar* Note : High Pressure pumps are available for selected sizes

Our progressive cavity pumps are used for High Viscous, Aggressive and abrasive media for low pulsation delivery in numerous Industrial, Hygienic, Wastewater, Sugar industries along with environmental engineering and numerous other industries.

Water & Waste Water, Environmental Industry, Food & Beverage, Oil & Gas, Chemicals & Pharmaceuticals, Minerals & Mining, Paper & Pulp, Agriculture, Solar, General Industry/Other, Potable Water Supply...

Paper, sugar, agriculture, oil & gas, paint, varnish, ink, mining, chemical, food, explosive, man made fibre, construction, wine & beverage, cattle feed, ceramic, edible oil, cosmetic, toiletries, dye stuff, marine, waste water treatment, pharma, power plant, distillation plant, fertilizers, steel industries...

We supply spare parts for the following pumps:

MONO, SEEPEX, NETZSCH, PCM, ALLWEILER, ROBBINS & MYERS, BORNEMANN, ORBIT, BELLIN, NOVA ROTORS, ROTOMAC, SYNO...

.jpg)